Plant commissioning

High-level commissioning services for your industrial instrumentation

Commissioning, the key to your project’s success

At CIRA, commissioning means ensuring every component of your system operates efficiently, safely, and in strict accordance with both industry standards and your specific requirements. This essential step prepares your facilities for flawless, long-term performance.

We begin with a thorough inspection of the mechanical and electrical installations, ensuring all connections are secure and compliant. Our teams then carry out precise sensor and instrument calibration to ensure measurement accuracy. Finally, we conduct comprehensive functional testing to verify control loop responsiveness under all operating conditions.

Why choose CIRA?

your productivity is our priority!

Commissioning objective

Our mission is to detect and resolve any issues or deviations before your system goes live. This proactive approach reduces the risk of failure, boosts immediate performance, and extends the lifespan of your equipment.

Choosing CIRA means trusting a team committed to delivering secure, reliable, and optimal system readiness—tailored to your specific operational needs.

Compliance verification

Ensuring all equipment meets regulatory standards for a safe and reliable installation.

Performance testing

Validating system efficiency from the outset—no surprises.

Fault detection and correction

Identifying and addressing defects to minimize downtime and ensure seamless operation.

Training & Documentation

Empowering your teams with the knowledge and materials to manage systems independently.

Tasks performed

Commissioning by CIRA, step by step

01

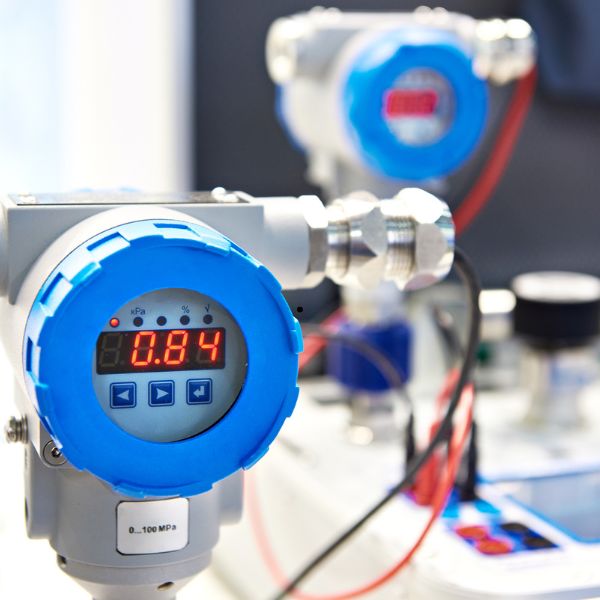

01Calibration

Calibrating transmitters involves comparing their measurements with known reference values to check and adjust their accuracy. This process ensures that the equipment delivers accurate and reliable readings, essential for the smooth running of industrial processes and operational safety.

Our priorities are the use of certified standards, compliance with standardized procedures, and the completion of calibration sheets. Calibration must be carried out regularly to maintain measurement integrity, taking into account environmental conditions and manufacturer-specified tolerances. Rigorous traceability is essential to ensure compliance with industry standards.

02

02Control loop synchronization

Control loop synchronization in industrial instrumentation involves coordinating the operations of several control loops to ensure optimum, consistent performance of the overall system. This involves forcing several values on a sensor, and checking that these values are correctly transmitted to the control room via the cabling.

Our priorities are the accuracy of values transmitted to the PLC, the accuracy of response times between loops, and continuous monitoring to detect and correct offsets. Clear documentation and regular testing are essential to maintain synchronization and guarantee system stability.

03

03Troubleshooting

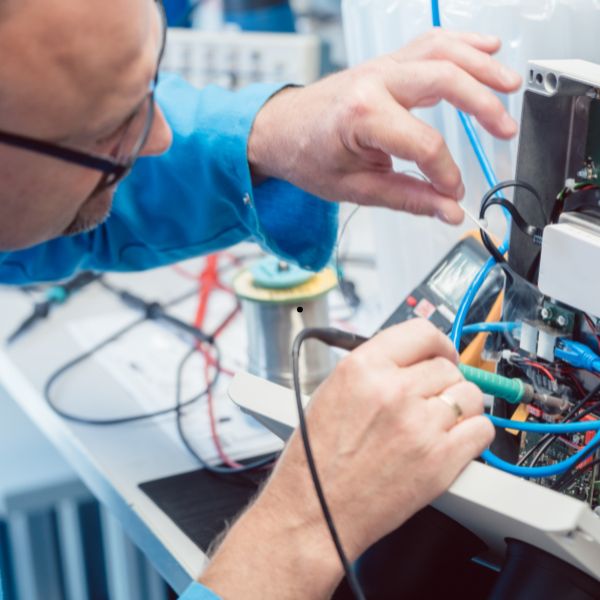

Troubleshooting involves identifying and resolving problems or anomalies in measurement and control systems. This involves diagnosing the causes of malfunctions, whether electrical, mechanical or PLC-related, and implementing solutions to restore equipment to proper working order.

Our priority is to work with the production department to identify faults. When a problem is reported, our instrument specialist talks to the operator of the unit concerned to locate the malfunction. Together, they analyze the various symptoms to determine when and where the system stopped working properly. This approach makes it possible to quickly distinguish whether the problem originates in the PLC or in another component, such as a valve or sensor, and considerably reduce downtime or system failure.

04

04Calibration and functional testing

Functional testing verifies that every component or system in a plant, unit or skid is operating correctly. Conducted in conjunction with design engineers or operators, these tests involve creating every conceivable operational condition and ensuring that equipment reacts as expected, even under extreme conditions. They also identify and correct unexpected behavior, such as an unexpected valve opening, to ensure system reliability.

Our priorities are compliance with standardized procedures, and accurate documentation of results. For functional testing, we simulate real-life operating conditions to verify all possible usage scenarios, and document results to ensure traceability and compliance with technical specifications.

05

05Controls and compliance

Control and compliance involve checking that equipment and processes comply with current standards and regulations. This involves ensuring that measuring and control instruments operate to defined specifications, and that operations are carried out in accordance with legal requirements and industry standards.

Our priorities are to ensure that equipment and accessories are installed in zones corresponding to their classification level (e.g. ATEX), and that the installation of the entire system is compliant. We inform the operator if an anomaly is detected. They also cover the implementation of regular verification procedures and the keeping of detailed documentation of inspection results. We also keep abreast of regulatory developments, and train staff in best practices to ensure ongoing compliance.

06

06Documentation

Documentation is essential to ensure traceability, maintenance and compliance of measurement and control systems. It encompasses the creation and management of documents detailing installation, calibration and maintenance procedures, as well as test and verification results.

Our priorities are to provide the operator’s methods department with all the information they need to keep their technical documentation up to date. This includes information on any modifications we make to the installation (equipment changes, wiring modifications), or any discrepancies we observe between documentation and reality in the field.

07

07On-call duty 3x8h – 2x8h

On-call means ensuring that technical staff are always available to intervene rapidly in the event of a problem or breakdown, on or off working days and hours. This ensures continuity of operations and minimizes interruptions.

We work 3x8h and 2x8h shifts to ensure that our on-site services are available for the full duration of operations, particularly during site shutdowns and restarts, which can take place over a relatively long continuous period, but are strategic in terms of productivity and safety.

Our priorities are absolute compliance with regulations, to guarantee our customers and employees the best possible availability and working conditions.

08

08Training

Industrial instrumentation training aims to enhance technical skills and optimize equipment operation. This includes teaching the fundamental and advanced principles of instrumentation, providing practical advice on the use and maintenance of equipment, and ensuring optimum use of systems.

Our priorities are the adaptability and relevance of training programs to meet the needs of industrial instrumentation professions and the specificities of different industries. Clear documentation and well-defined assessment procedures are developed.